Transforming plastic waste into everyday products.

[blog-marquee]

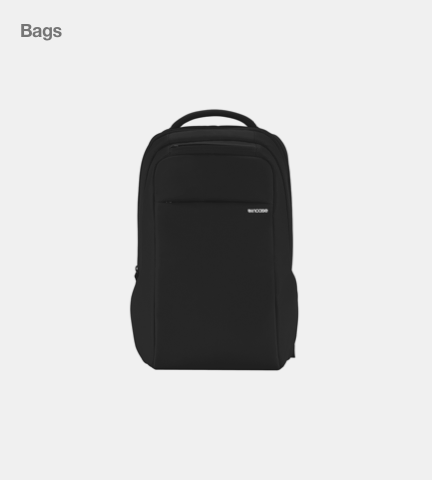

Incase x BIONIC

[/blog-marquee]

From the very start Incase has strived to deliver a better experience through good design. Over time that philosophy has evolved to include a commitment to responsible design initiatives. That includes creating some of our products from innovative fabrics consisting of sustainable, recyclable materials, generated by emission-saving production practices. Our BIONIC collection is a great example. Why? Because it’s our — and everyone’s — responsibility to do what we can to reduce our impact on the environment and make the planet a better place to live.

https://www.youtube.com/watch?v=J09OWTmXnP8

That’s why we’re proud to partner with BIONIC®, a material engineering company supplying consumer and industrial markets with fully traceable, high-grade textiles and polymers made with plastic recovered from coastal communities. The high-performance yarns, fabrics and textiles BIONIC creates from this discarded waste has revolutionized its industry, while simultaneously helping clean up marine environments.

Together, Incase and BIONIC are issuing a call to action to the global community to get tougher, more resilient and more united in our efforts to clean up the environment. Part of that is knowing what the things you buy and use are made of and where the materials come from. That’s why it’s imperative to BIONIC that their raw materials are fully traceable, so they know exactly where they come from—the country, the community, and often the very beach. They know because they were there when they were recovered, which means YOU know too. Following are the key steps necessary to transforming discarded plastic waste into superior materials, like those used in Incase’s BIONIC collection.

[carousel]

[/carousel]

STEP ONE: Outreach & Recovery

BIONIC starts by identifying a coastline in need of cleanup and reaching out to the local community to rally support. That includes families, friends, school groups, non-profit organizations; anyone interested in a cleaner coast. Recycling stations are set up and commercial collection points are designated, operated by BIONIC employees, but the actual clean-up work is typically a community effort. Together they closely and methodically comb the chosen beach and coastal area for plastic products and other forms of waste. BIONIC requires PET and HDPE plastics (soda bottles, milk jugs, etcetera), but they pick up all forms of plastics, glass and recyclables and send them to appropriate recycling centers. Because the best thing for the planet is to eradicate all the waste, not just some of it.

[carousel image2]

[/carousel image2]

STEP TWO: Sorting, Processing & Pelletizing

Step two is the amazing transformation of recovered plastic into useful material. It begins at a BIONIC-built regional facility located near the recovery site, where the plastic is sorted by type and color, compacted, and ground into flakes. The flakes are shipped to another facility to be cleaned of contaminants, like sand and label remnants, then melted together and passed through a device called a spinneret. The spinneret restructures the plastic into polymer and extrudes it in long threads that are cut into small pellets, which form the base material of every high-tech yarn and thread BIONIC makes -- including what Incase uses for our BIONIC Collection.

[carousel image3]

[/carousel image]

STEP THREE: Creating a Stronger Thread

The final step is where the real magic happens. It occurs at the many partner mills BIOINIC employs worldwide, where the polymer pellets are again melted and extruded in long filaments that are spun into three yarns — FLX, DPX and HLX. FLX is 100% recycled plastic. DPX blends recycled plastic with natural and synthetic fibers for a softer texture. HLX uses extra fibers for a three-layer construction with a recycled-plastic heart. BIONIC can weave an almost infinite array of textiles with these three yarns, including the high-performance fabrics used for Incase’s BIONIC collection.

The value of the above three-step process can’t be underestimated. BIONIC turns pollution into a positive, which aligns cleanly with Incase’s commitment to using sustainable materials whenever we can. The result -- a cleaner, better environment and pleasing, high-performing products

[standout-image]

[/standout-image]

Content provided by https://bionicyarn.com/

[collection]

Dimensions

Dimensions

Compatibility

Compatibility

Material

Material